This comprehensive guide clarifies the intricacies of your tractor's power take-off (PTO) system, empowering you to optimize farm operations and enhance efficiency. We'll explore PTO types, safety protocols, maintenance best practices, and future technological advancements. For more on tractor safety, check out this helpful resource on tractor safety.

Understanding Your Tractor's PTO System

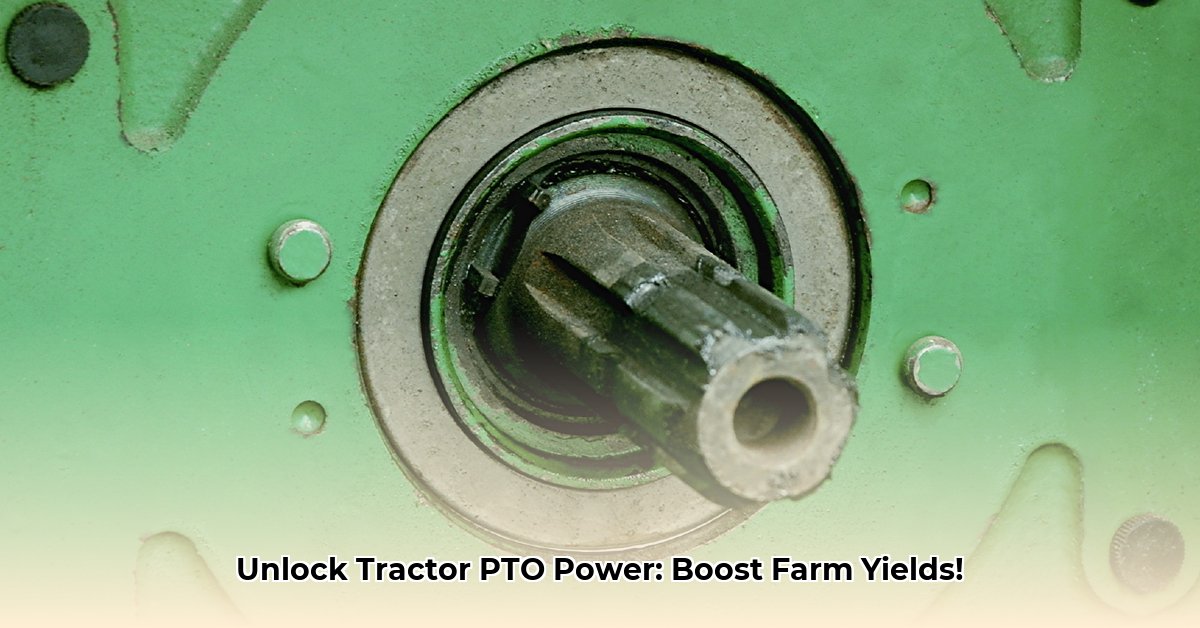

Think of your tractor as a powerful engine; the PTO is the crucial link connecting it to your implements. It efficiently transfers power from the tractor's engine to various implements like mowers, balers, and tillers, eliminating the need for individual motors. This significantly streamlines operations and boosts productivity on your farm. Don't underestimate its importance in modern agriculture!

Types of Tractor PTO Systems: Choosing the Right Fit

Different PTO types cater to diverse needs and budgets. Selecting the optimal system depends on your farm's operational requirements and scale.

Transmission PTO: This basic type directly links to your tractor's transmission. The PTO is active only when the tractor is moving. Simple and reliable, but its inflexibility limits adaptability.

Live PTO: This system offers improved versatility. It operates independently of your tractor's movement, enabling the use of powered implements even when stationary. This enhances convenience and adaptability for a wider range of tasks.

Independent PTO: This advanced system provides complete control. The PTO operates independently of the tractor's transmission and engine, allowing for precise speed and power adjustments. This maximizes flexibility and efficiency, offering the greatest control and precision.

What PTO type best suits your current operations? Consider the types of implements you regularly use and the level of control you need.

PTO Shaft Speed and Compatibility: A Critical Match

Most tractors offer two common PTO speeds: 540 revolutions per minute (RPM) and 1000 RPM. 540 RPM generally suits many implements, while 1000 RPM is ideal for high-power applications. However, mismatched speeds can damage equipment and pose significant safety risks. Always consult your tractor and implement manuals to ensure compatibility. Remember, using the incorrect shaft type (metric vs. standard) can be catastrophic. Double-check compatibility meticulously before operation.

Engaging Your PTO System: A Step-by-Step Safety Guide

Safety is paramount when using PTO-driven implements. Follow these steps for safe operation:

- Secure the Implement: Ensure the implement is correctly attached and all safety mechanisms are securely engaged. A loose connection can have devastating consequences.

- Stop and Disengage: Bring your tractor to a complete stop and fully depress the clutch before engaging the PTO.

- Engage the PTO: Follow your tractor’s manual instructions. Usually, this involves a lever or a switch.

- Start the Implement: Engage the implement's power source after successful PTO engagement.

- Maintain Vigilant Monitoring: Constantly monitor the tractor and implement's performance. Address any issues immediately.

- Disengage Properly: Before dismounting or leaving the tractor, always disengage the PTO and implement's power source.

Following these steps can drastically reduce the risk of accidents. Remember, consistent vigilance is your best defense.

Maintaining Your PTO System: Proactive Measures for Longevity

Regular maintenance is crucial for maximizing PTO lifespan and efficiency. Follow these guidelines:

- Regular Inspections: Regularly inspect the PTO shaft and components for wear, bends, or damage. Replace worn parts promptly.

- Consistent Lubrication: Maintain proper lubrication according to the tractor’s maintenance schedule. This minimizes wear and tear.

- Fluid Level Checks: Ensure the correct PTO fluid levels are maintained. Low fluid levels lead to overheating and potential failure.

Consistent maintenance not only extends the life of your PTO but also enhances its performance and efficiency. Regular checks can avoid costly repairs and downtime.

PTO Safety: A Continuous Commitment

Never underestimate the potential dangers of working with heavy machinery. Always adhere to safety guidelines provided in your tractor and implement manuals. Never reach near moving parts while the PTO is engaged. Ensure all safety mechanisms are functional before operation.

Choosing the Right PTO System: Tailoring to Your Needs

The ideal PTO system depends entirely on your farming operations. Consider factors like flexibility, control, and budget. If flexibility is paramount, a live PTO is a sensible choice. For ultimate control, an independent PTO is recommended.

Future Trends in PTO Technology: Innovations on the Horizon

Ongoing research and development promise advancements in PTO technology. Expect more energy-efficient systems and seamless integration with other farm technologies in the near future. Smart PTOs, incorporating automation and optimization, will further enhance efficiency and sustainability.

Key Takeaways:

- Understanding the different PTO types is essential for optimal system selection.

- Prioritizing safety measures is critical for accident prevention.

- Energy-efficient PTOs contribute to sustainable farming practices.

- Comprehensive cost-benefit analyses are essential to making financially sound decisions.

- Regular maintenance extends equipment lifespan, promoting sustainability.